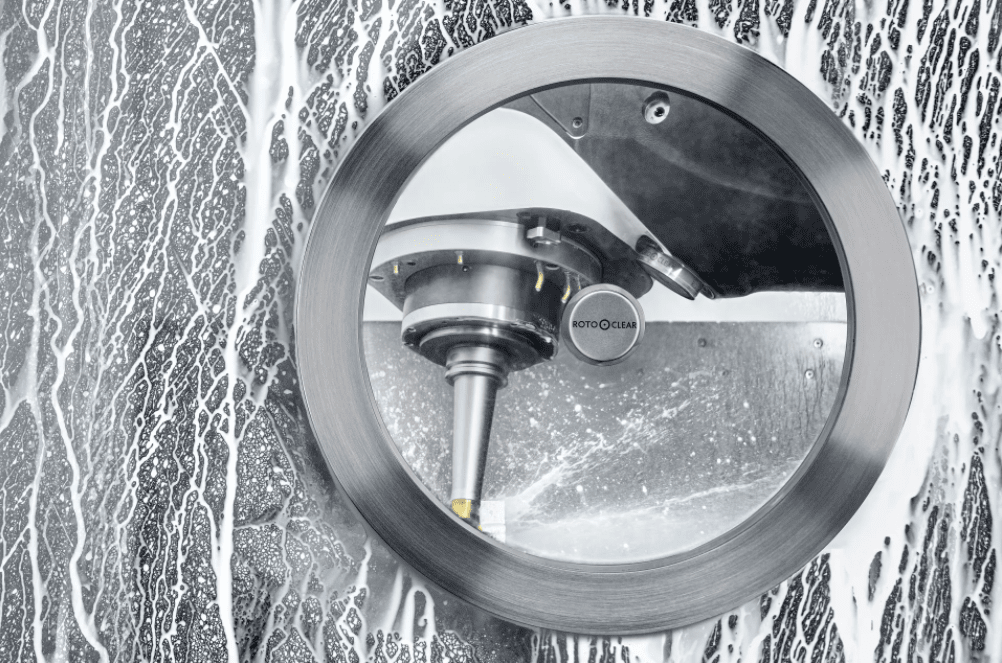

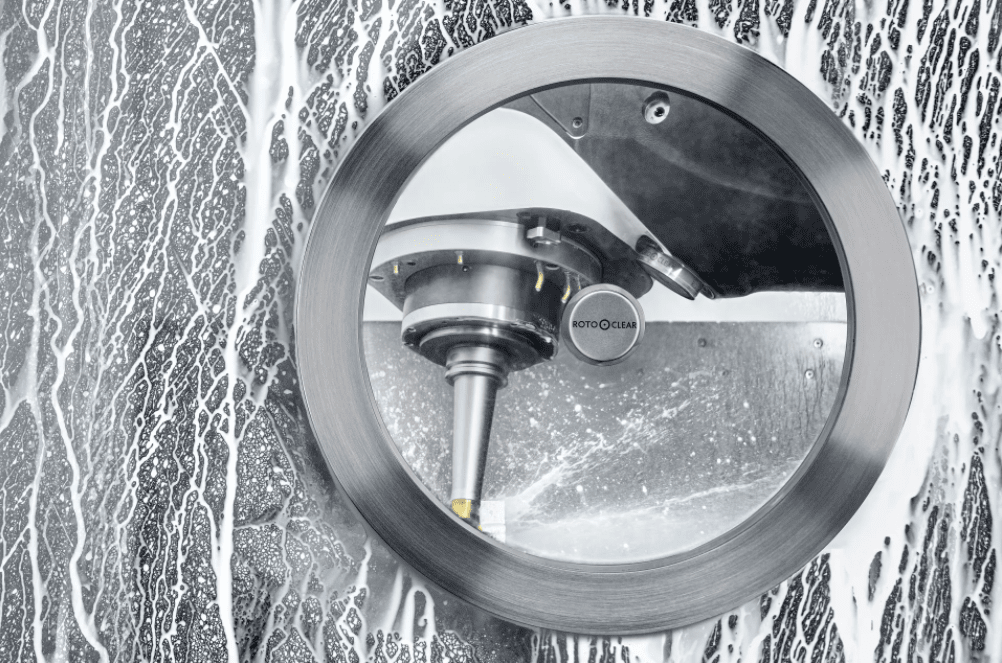

Hvad Rotoclear S3 tilbyder dig

Muligheden for løbende visuel overvågning gør opstarten lettere, hurtigere, sikrere og mere effektiv.

Et frit indblik i dine processer lader dig også minimere spildudgifter, mens Rotoclear S3 betydeligt reducerer mængden af nødvendig tidskrævende rengøring.

Rotoclear S3’s patenterede drivmekanisme sikrer også meget korte vedligeholdelsestider, da rotoren kan udskiftes hurtigt hvis nødvendigt.

Læs den nye brochure her.

Besøg også produktsiden på rotoclear.com for mere information om Rotoclear S3.