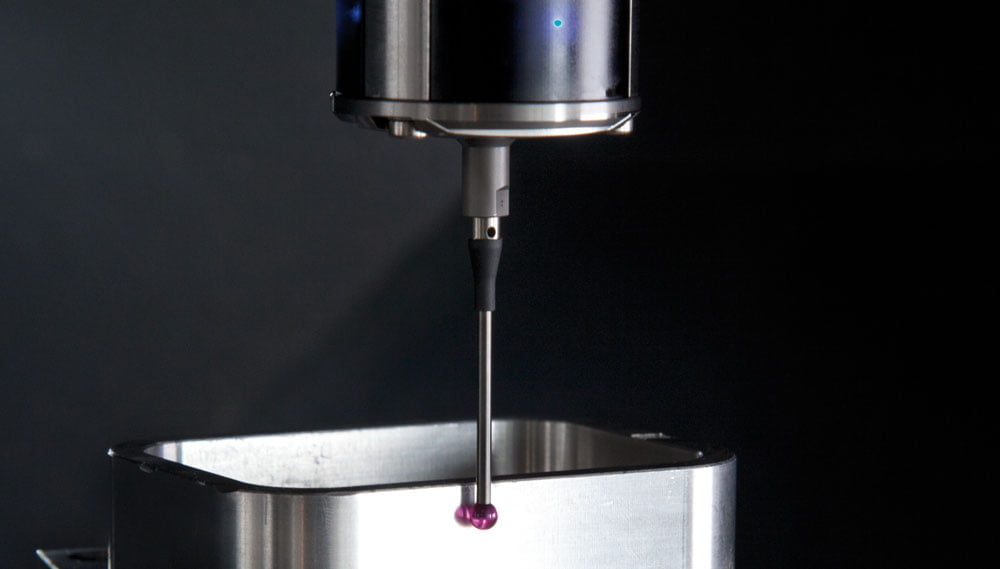

Reduced set-up time

HEIDENHAIN’s TS 3D Touch systems allow you to measure your workpiece, quickly and simply without the use of manual dial gauges.

The 3D Probe adjusts the coordinate system so you can quickly start your machining.

Minimize scrap

HEIDENHAIN’s TS 3D Probes minimize the risk of scrapped items caused by manual alignment errors.

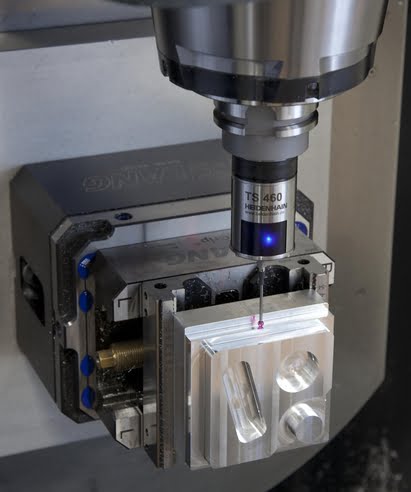

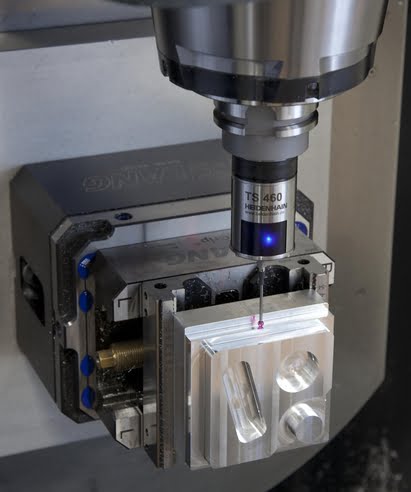

Monitoring your tools

Wear or tool breakage that is not detected for a long time, especially during unattended operation, results in defective parts and increases the cost unnecessarily.

HEIDENHAIN’s TT and TL Touch probes allow automatic tool measurement and detection of fractures while the machine is running